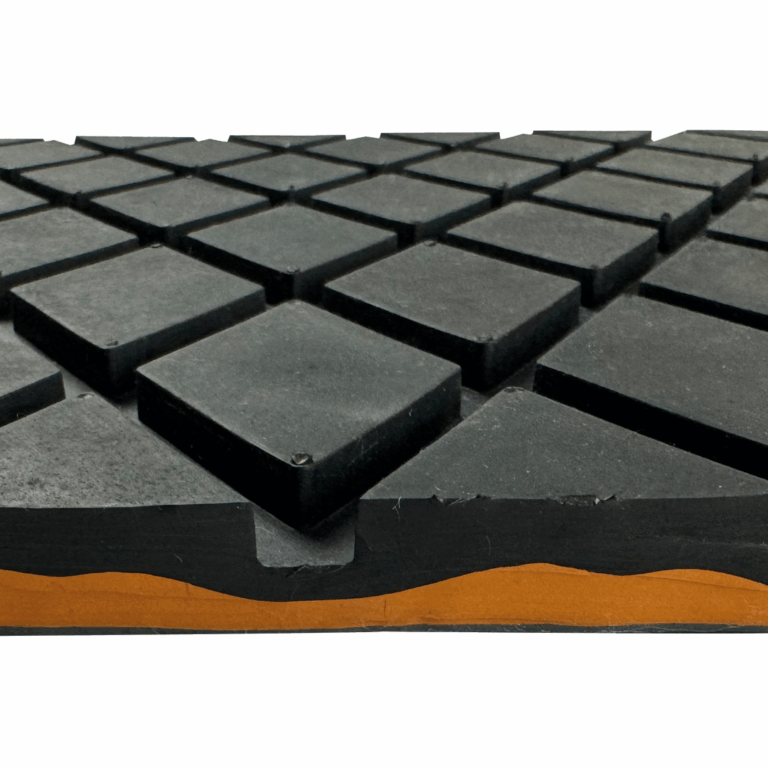

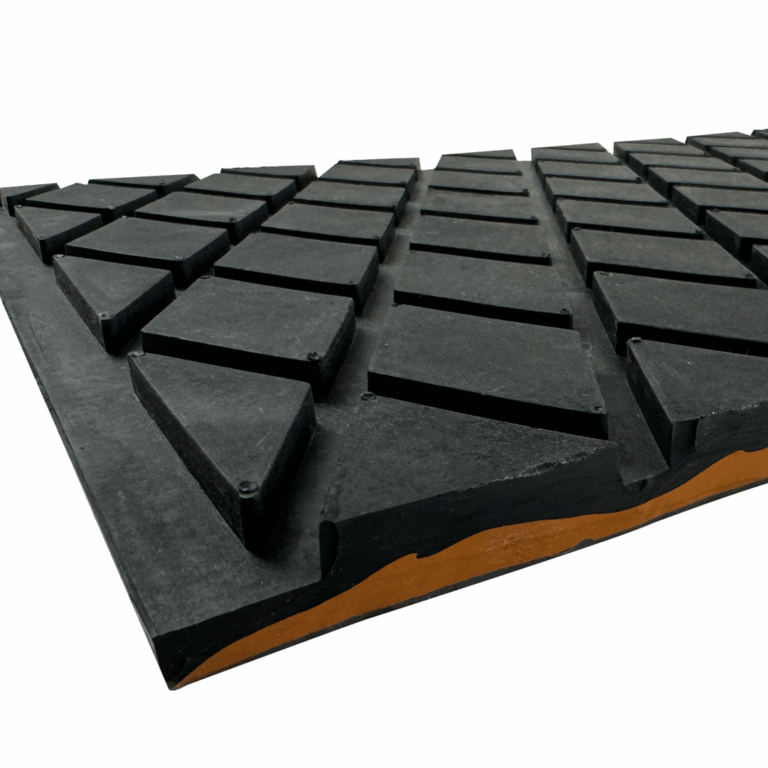

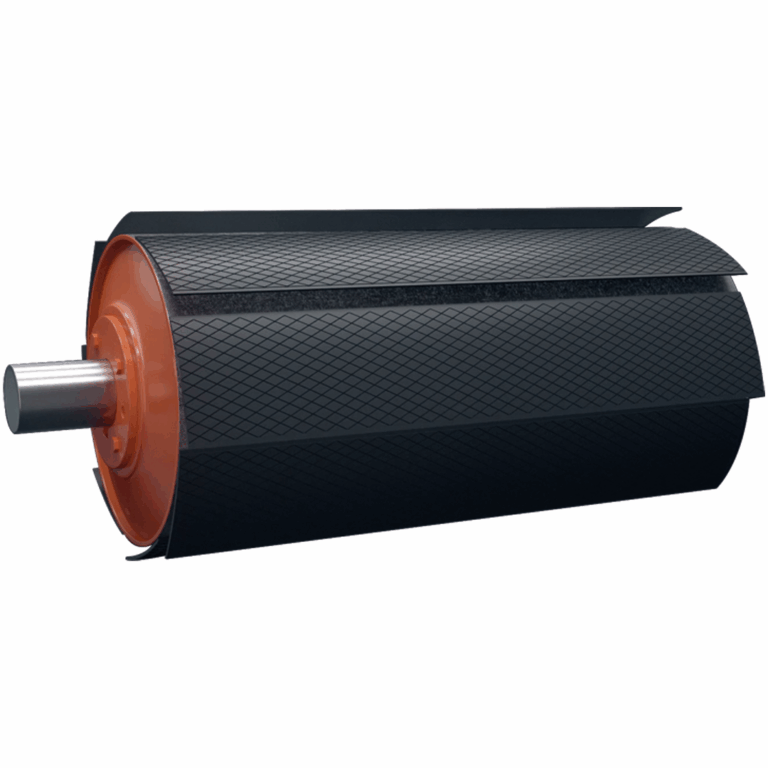

Modular plates developed for high-performance lining, adaptable to a variety of operating conditions on conveyors. Supplied in modular plates with diamond grooves, offering excellent abrasion resistance and long service life. Suitable for both drive drums (low-tension conveyors) and driven drums. They provide greater versatility and ease of application due to the modular design. Supplied with a CR layer (self-vulcanizing). Manufactured in thicknesses of 10, 12, 15, and 20 mm for application on drums of different diameters and operational demands. Plates supplied with 500 mm modules and widths for drums up to 3,300 mm. Available widths from 600 to 3,300 mm.

Also available in V-0 version, whose compound characteristics meet the V-0 classification of the UL94 standard. Its high abrasion and impact resistance is combined with flame-retardant and self-extinguishing properties, making it an excellent solution for industrial applications with higher flammability risk.

Contact us. We manufacture custom solutions, increasing cost-efficiency and reducing waste.

CR Layer

Some Vulcaflex modular linings can also be supplied with a CR layer (self-vulcanizing), providing greater ease of application and a considerable increase in metal-rubber adhesion in cold vulcanization. Mechanical cleaning of the rubber is not required.

CR+ Layer

The CR+ layer is an additional self-vulcanizing layer that covers the lateral faces and edges of the lining plates, promoting:

• Gains in Productivity and Safety for the Vulcanizer, as it is not necessary to grind the faces and edges of the rubber plate to apply the adhesive solution and install Vedaflex finishing tapes, reducing adhesion and sealing failures during the drum lining process;

• Improvements in Drum Lining Finish Application, helping to reduce adhesion failures at this stage of the process.

DV Layer

The plates can be manufactured with two different colors in their thickness, allowing the creation of a Visual Wear Limit (DV) that enables maintenance professionals to identify the wear level as soon as the new rubber color is observed after a certain reduction in the lining thickness. This allows maintenance decisions regarding the scheduling and replacement of the lining, avoiding unwanted events with damage to the drum shell, unexpected maintenance stops, and production losses.

Properties:

• Drum width manufacturing up to 2,600 mm;

• Replaces grooved rubber sheets;

• Allows modular maintenance without removing the drum;

• Easy handling and application;

• Less effort to move the plates;

• Self-vulcanizing CR layer with greater metal-rubber adhesion;

• Drum protection against wear and corrosion;

Assine a nossa newsletter e receba dicas, ofertas e novidades Vulcaflex. Não se preocupe, não iremos lotar a sua caixa de entrada :)

Rua Afonso Egydio de Souza, 540, Distrito Industrial | Uberlândia-MG, Brasil | CEP: 38.402-332

Rua Fiat, 41, Jardim Piemonte | Betim-MG, Brasil | CEP: 32.689-366

Av. Carlos Gomes de Sá, 335, Mata da Praia | Vitória-ES | CEP: 29.066-040 (Ed. PlusOffice)

Rua Antônio Thomaz Ferreira de Rezende, 1343, Marta Helena | Uberlândia-MG, Brasil | CEP: 38.402-236

Avenida Redenção, Quadra 15, Lote 48, Residencial Linha Verde | Parauapebas-PA, Brasil | CEP: 68.515-000

Región Metropolitana | Santiago, Chile | CEP: 75.500-00